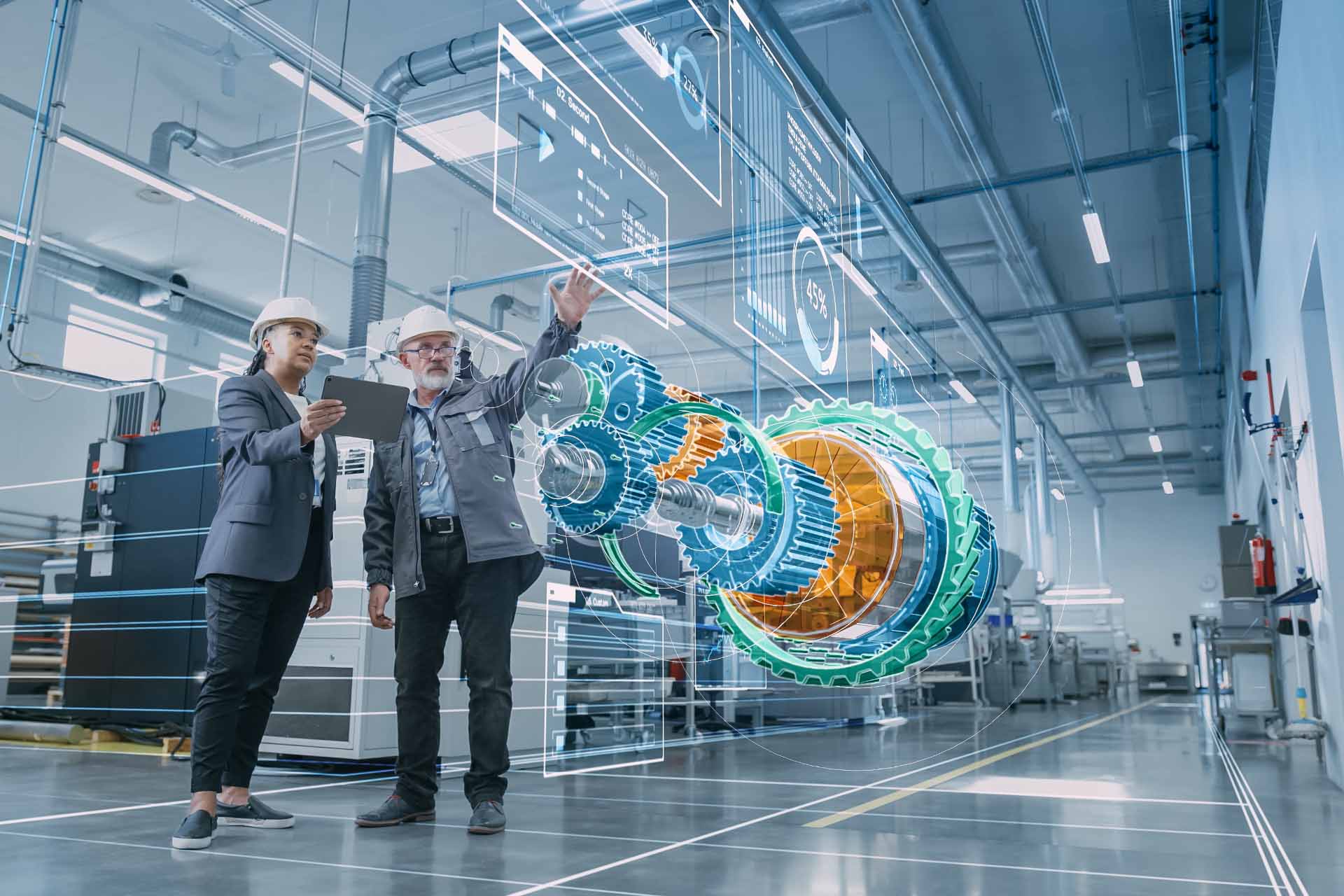

Digitalisation in Machinery and Engineering: Connecting Processes and Maximising Potential

Simplify processes. Reduce your teams' workload. Serve customers digitally and quickly. Those who intelligently connect systems and data in machinery and engineering are one step ahead in terms of technology and organisation.

However, it is precisely in complex structures that the connection is often missing. Systems exist, but they do not communicate with each other. An integrated platform makes all the difference here – for greater clarity, speed and impact.

Together we connect your systems to form a powerful digital experience platform (DXP). Upon request, we can incorporate smart technologies such as AI and process automation if they support your processes.

This makes complexity manageable and your digital infrastructure fit for international scaling, rising expectations and new business models.

Those who link their data, systems and processes correctly create space for the following:

- Efficient workflows

- Stable growth

- Digital innovation

- International scaling

Consulting Session: Explore Your Opportunities

Your Contact for Further Questions

You Will Hear from Us Soon

- Our experts will take your enquiry and get back to you within one working day.

Challenges and Solutions in Machinery and Engineering

Quotes taking too long? Save time in sales.

Sales teams lose time when systems do not work together, resulting in a lack of important information about products and customers.

The solution: a central database, a customer relationship management (CRM) system and structured processes. This creates an overall picture that speeds up quoting and simplifies decisions.

BODE, a manufacturer of door systems for rail vehicles, shows how it is done. With a consolidated CRM solution, processes were simplified and customer data was harnessed. This lays the foundation for faster quotes and strategic sales.

Data chaos in product management? Create structure with PIM.

Structured product data is the basis for successful sales, e-commerce and targeted customer communication. Combined with customer data, it enables more personalised offers, precise product recommendations and automated processes.

A data management system adds structure, avoids duplicates and simplifies translations.

Walter AG, an international manufacturer of precision tools, leads by example. With a product information management (PIM) system, global data management becomes more efficient and time to market is significantly reduced.

Complex products, confusing user guidance? Make it easier to get started.

Whether customer portal, product configurator or digital service tool – technically sophisticated products need intuitive user guidance.

Targeted user experience design makes complex product worlds understandable and guides users intuitively through the purchasing process, thereby boosting conversion rates. This applies to both B2B and B2C.

STIHL, one of the leading manufacturers of gardening equipment, successfully implemented this. Thanks to clear user guidance, customers can find their way around faster. This improves the shopping experience while reducing the burden on sales teams.

Manual processes? Automate them with AI and logic.

When processes are predominantly manual and a shortage of skilled labour exists, valuable potential often remains untapped.

Automated workflows and AI-powered analytics relieve teams of repetitive tasks, increase efficiency and create a reliable database for better decisions. This turns data-driven business into a real competitive advantage.

Saurer, an international supplier of textile machinery and systems, demonstrated this with data-driven services, automated processes and intelligent dashboards, resulting in less effort, shorter response times and capacity for new business models.

No consistent digital experience? Create an integrated platform.

Today's customers expect more than just an online shop. They want consistent and powerful digital touchpoints – from product finder to service enquiry.

A DXP combines e-commerce, content management, product configuration and self-service in an integrated architecture that is customisable, scalable and future-proof.

TROX specialises in air conditioning and ventilation systems and demonstrates how an integrated platform solution works. By seamlessly linking its online shop, product configurator and customer portal, the company creates a consistent digital experience from research to order.

Is digitalisation stalling during rollouts? Scale with cloud architecture.

Centralised IT infrastructures often reach their limits when markets grow or new subsidiaries are added.

Cloud solutions provide the necessary flexibility, as systems can be rolled out, expanded and adapted worldwide.

Krones, a manufacturer of filling and packaging technology, and Angst+Pfister, a supplier of component and engineering solutions, rely on scalable platforms that meet local requirements and remain centrally controllable. The intelligent networking of systems creates an infrastructure that grows flexibly while ensuring clear standards.

These Companies from the Machinery and Engineering Industry Trust Our Expertise

Expertise for Your Next Digital Steps

Digitalisation with a Plan: These Services Bring You Forward

Frequently Asked Questions

Which processes in mechanical engineering are particularly well suited for digitalisation?

Sales, service and data processes, e.g. CRM, PIM, e-commerce, configurators and predictive maintenance, are particularly suitable. Integrating existing systems into a centralised platform and switching to cloud-based architectures creates measurable added value.

How do you start a digital project without having to rebuild everything at once?

Start with a clearly defined use case, e.g. CRM or product data management, and scale up gradually from there. We are happy to support you in your endeavours and work with you to identify your priorities and goals.

What are typical stumbling blocks in digitalisation projects?

Progress is often slowed down by unconnected systems, unclear responsibilities, a lack of change management or too many requirements. We work with you to prioritise the most important steps and ensure that your project progresses in a structured and realistic manner.

How can you improve the digital customer experience for complex products?

Through intuitive user guidance, clear navigation and intelligent features such as self-service, configurators or personalised content. A good customer experience makes products that require explanation accessible, improves conversion rates and reduces the burden on service teams.

How can you get started with AI in mechanical engineering?

Start with processes that are driven by data and repetitive, e.g. predictive maintenance, automated quoting or chatbots in service. A strong data foundation and structured processes are crucial. Only then can AI deliver real benefits.